Surface Treatment and Finishing

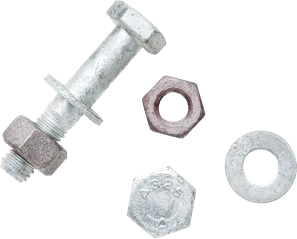

Hot Dip Galvanizing

The equipment of our Galvano plating facility includes centrifugal baskets of 16 “diameter and 24” deep and a 360 cubic foot zinc bath.

Hot Dip Galvanizing is the plating of choice for outdoor applications. This process is carried out by submerging steel parts in a bath of molten zinc. There is enough zinc applied to offer a sacrificial protection: in the event the base metal would be exposed, the zinc would corrode first.

Once the parts are taken out of the zinc bath, they are centrifuged to remove the excess zinc from the threaded areas: Galvano process is optimized for small parts, ensuring a high-quality finish on fasteners.

Get a quote